Supporting an oil depot in Xizang aviation fuel coalescer filter separator site

Project profile

Project profile

Field condition:After two major expansions and several modifications, the refined oil reserve has grown from 33,000 cubic meters to 86,000 cubic meters, and the oil business has expanded from the original two varieties to cover five varieties of diesel-20, -10, 0, and gasoline 90, 93, and the turnover of refined oil has jumped from the original 50,000 tons to 235,000 tons.

Technical parameter:

1. Initial differential pressure: <0.05MPa

2. Dewatering capacity: water content ≤0.5%, 3%, 10%

3. Pollution capacity: 1.3g/(rated flow rate of L/min), 2.64g/L/min, 4g/L/min

4. Fuel cleanliness after filtration:

(1) Free water content: <15PPm

(2) Solid impurity content: <0.26mg/L

(3) Fiber content: <10 pieces /L

5. Allowable working differential pressure: 0.1Mpa

6. Filter element structural strength: >0.7Mpa

Applicable fliud:

1. Various chlorofluorocarbons

2. Aviation fuel, gasoline, kerosene, diesel

3. Liquefied petroleum gas, petroleum coke, naphtha,

4. Benzene, toluene, xylene, isopropylbenzene,

5. Polypropylbenzene, cyclohexane, isopropyl alcohol, cyclohexanol, cyclohexanone, etc.

Function:

1. Filtration and dehydration of final products (gasoline, kerosene, diesel and jet fuel, etc.)

2. Removal of lye after alkali treatment process

3. In the catalytic, cracking process intermediate filtration and dehydration to prevent catalyst poisoning

4. Separation of water and amine in liquefied petroleum gas

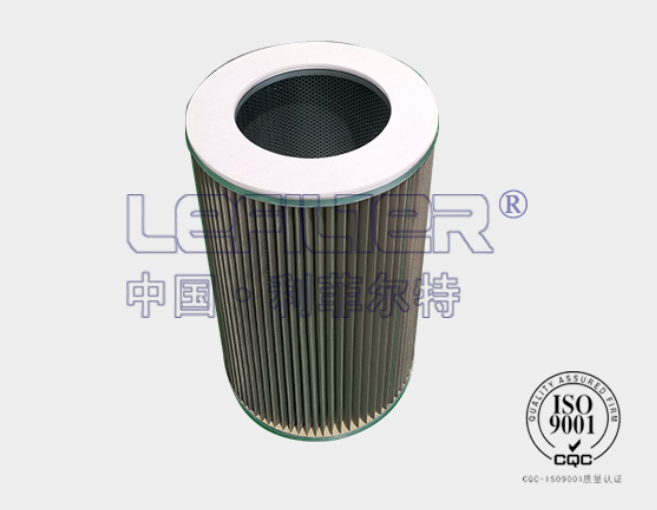

Performance parameter

Performance parameter

Equipment configuration and requirements

Equipment configuration and requirements

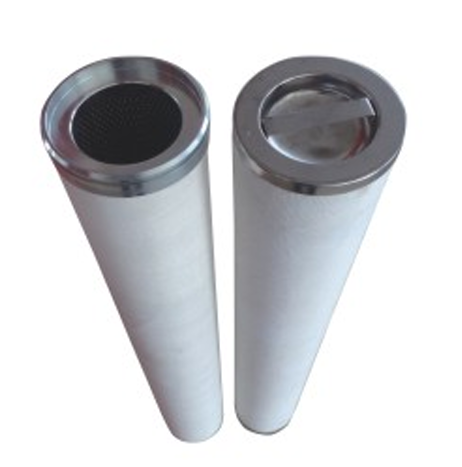

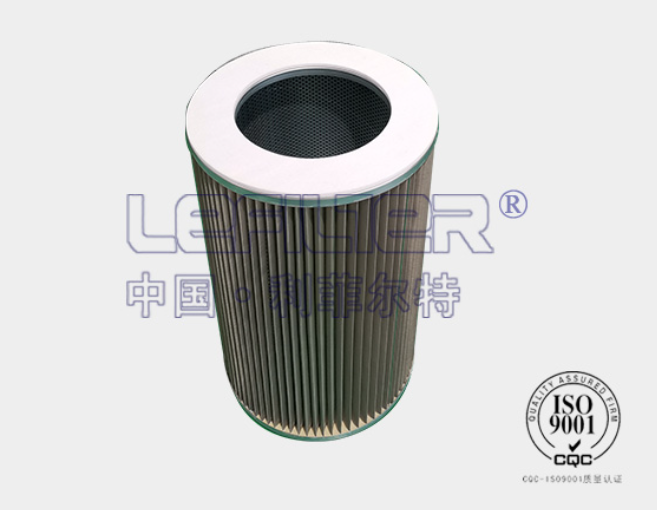

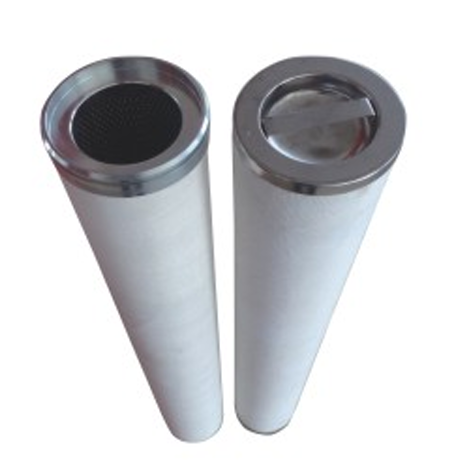

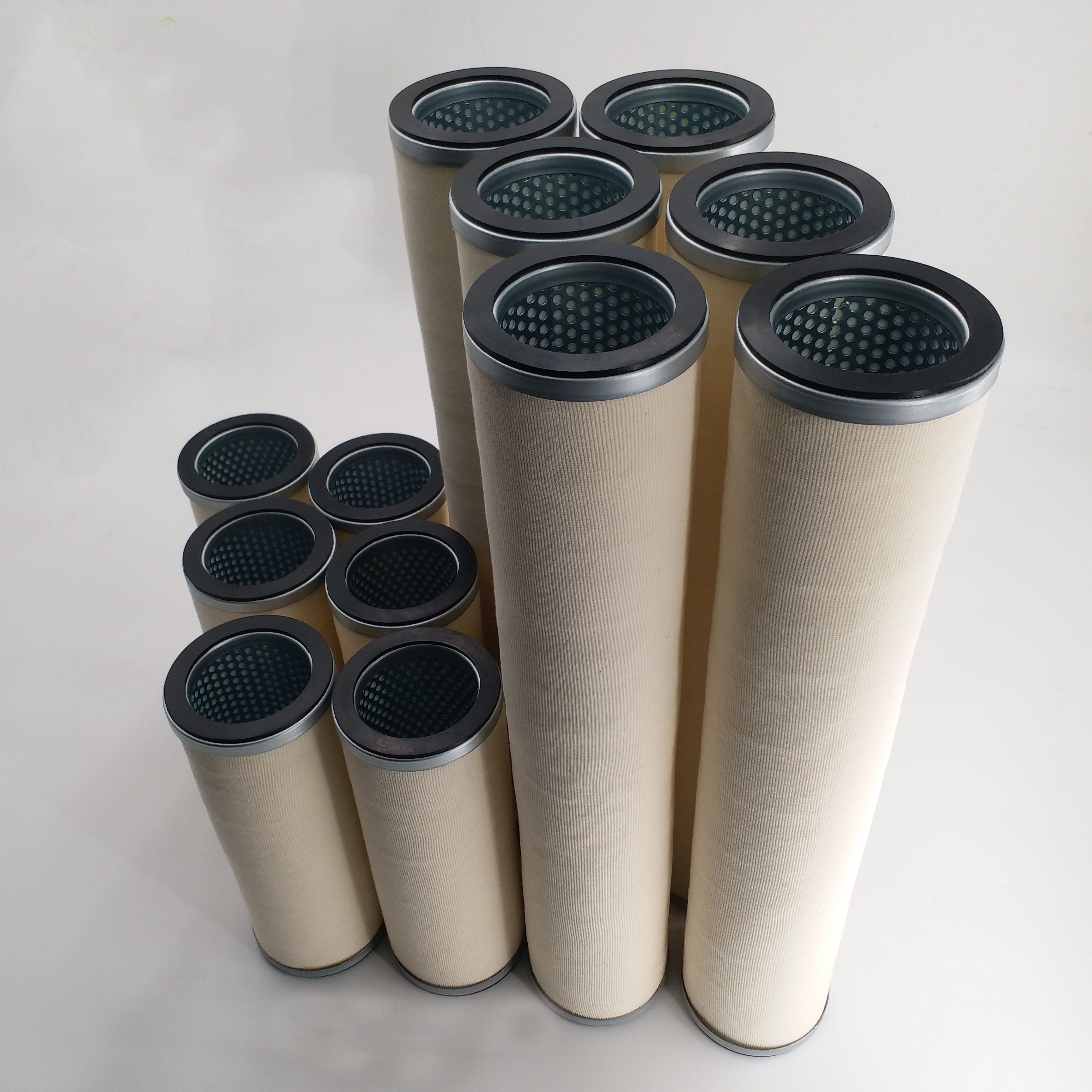

Production and delivery site

Production and delivery site

PRODUCT APPLICATION FIELD

ONLINE MESSAGE