Natural Gas Filter Element Model PCHG-12 In Petroleum Industry

Natural gas filter element is suitable for gas - liquid and liquid - solid separation of natural gas, artificial gas and other non - corrosive gases, such as nitrogen, carbon dioxide, propane, butane, etc. It is a necessary separation and purification equipment component of natural gas gathering and transportation pipeline, gas gathering station, pressure station, sub - transmission station, pigging station, terminal station and various application fields. It can effectively filter the dirt in the pipeline and the peeling debris of the pipe wall, so as to ensure the safe operation of the gas transmission and gas equipment, and meet the quality requirements of the pipeline transportation and users. Among them, the demand for coalescing filter element is very large.

Model:

PCHG-12

:

Product Introduction

Introduction

Natural gas filter element is suitable for gas - liquid and liquid - solid separation of natural gas, artificial gas and other non - corrosive gases, such as nitrogen, carbon dioxide, propane, butane, etc. It is a necessary separation and purification equipment component of natural gas gathering and transportation pipeline, gas gathering station, pressure station, sub - transmission station, pigging station, terminal station and various application fields. It can effectively filter the dirt in the pipeline and the peeling debris of the pipe wall, so as to ensure the safe operation of the gas transmission and gas equipment, and meet the quality requirements of the pipeline transportation and users. Among them, the demand for coalescing filter element is very large.

Technical data

Filtration Precision

Particles: 0.5μm for solid contaminants like dust and rust.

Emulsified water: 2μm for separating liquid droplets.

Flow Rate

25 Nm³/h under standard conditions. Can vary with system size and pressure.

Working Pressure

Max: 3 MPa for high - pressure applications.

Min: 0.3 MPa for flexibility in different setups.

Working Temperature

15℃ to 120℃ suitable for a wide range of environments.

Materials

Filter layer: Polyester fiber for effective filtration.

Support layers: Stainless steel for structural integrity.

Interface Size

Connection: Flange with 2" diameter for easy installation.

Application

Natural Gas Transmission

High - Efficiency Filtration

Natural gas filter elements use high - precision systems. They capture sub - micron solid particles and liquid droplets, purifying gas to strict standards. By removing contaminants, they reduce damage risks to downstream compressors, valves, and meters, thus extending equipment lifespan and cutting maintenance costs.

Optimal Flow Design

Engineered for smooth gas flow, these filters minimize pressure drop. They adapt to different flow needs in small or large - scale setups, remaining stable despite changes in pressure differentials and gas viscosity, ensuring a consistent gas - flow rate.

Robust Pressure Resistance

Built to withstand high pressures, they're suitable for long - distance pipelines and high - pressure compression stations. Their materials and construction ensure reliable operation under pressure, preventing system failures and safety hazards.

Broad Temperature Adaptability

Filter elements can function across a wide temperature range. Whether gas is cold during extraction or heated during processing, they work effectively, enabling continuous operation in various regions and seasons.

Durable and Corrosion - Resistant Materials

Filter media resists corrosion and has high porosity for gas flow. Inner supports offer mechanical strength, and outer housings protect against damage and maintain seals. This combination ensures long - term, reliable performance in harsh conditions.

User - Friendly Connection Design

Inlet and outlet connections are easy to install. Using industry - recognized types, they attach quickly to standard pipeline parts, reducing installation time and cost while preventing leaks for efficient gas transfer.

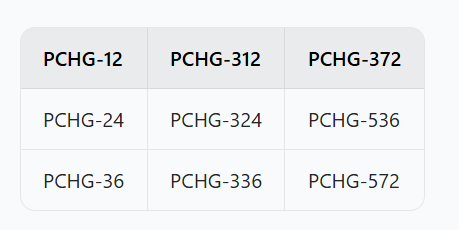

Other models optional:

Product Technical Parameters

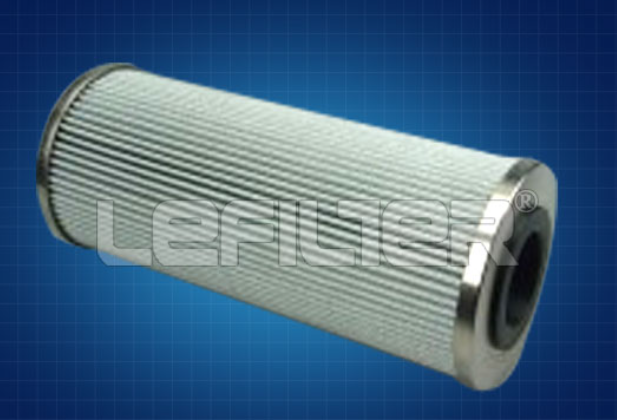

Product Display

ONLINE MESSAGE