Two-stage coalescer-separator filter vessels

Two-stage coalescer-separator filter vessels are the primary defense against fuel contamination by water and dirt. The coalescer separator housings contain both first-stage coalescer and second-stage separator cartridges with no internal moving parts.Our two-stage coalescer separators will continuously remove solids and water contaminants from aviation fuels & other industrial oils. Vertical and horizontal housing designs are available with a wide selection of coalescer and separator cartridges to meet specific applications.

Filter:

coalescer separator filter

:

Product Introduction

I. Introduction:

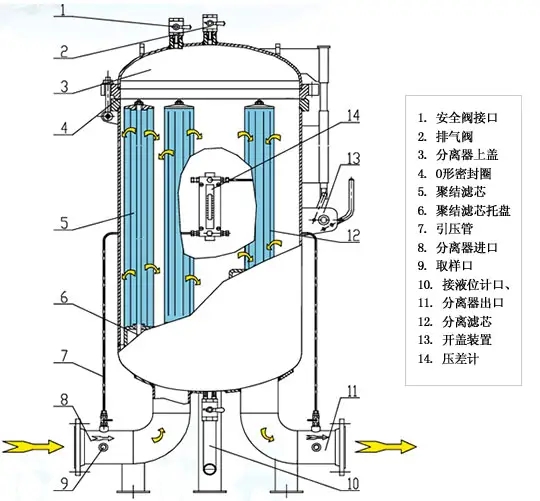

Two-stage coalescer-separator filter vessels are the primary defense against fuel contamination by water and dirt. The coalescer separator housings contain both first-stage coalescer and second-stage separator cartridges with no internal moving parts.

Our two-stage coalescer separators will continuously remove solids and water contaminants from aviation fuels & other industrial oils. Vertical and horizontal housing designs are available with a wide selection of coalescer and separator cartridges to meet specific applications.

II. Working principle:

The oil is pumped under pressure to flow through the housing inlet chamber and inside/out through the multi-media coalescer cartridge. This specially developed multi-media cartridge configuration traps and holds minute solid particles to less than one micron, while forcing small water droplets to commingle and grow into heavier, larger drops that fall by gravity to the housing sump area. The cleaned fuel continues to flow outside/in through the second-stage separator cartridges. These separator cartridges strip any remaining water droplets from the fuel allowing only clean, dry fuel to pass.

IV.

III. Inner spare parts:

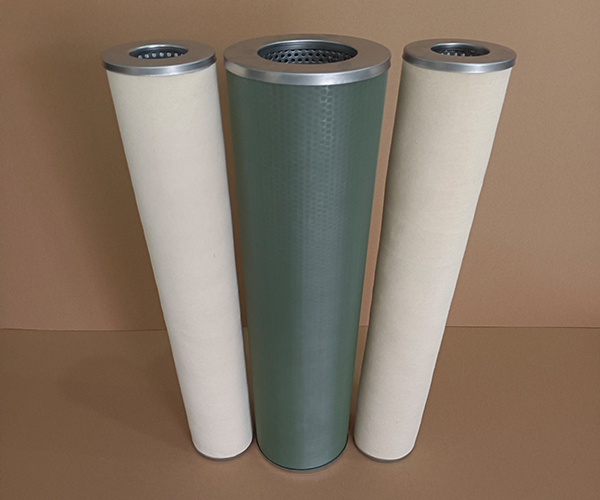

Coalescer Cartridge Separator Cartridge

IV.Application:

Product Technical Parameters

Product Display

ONLINE MESSAGE