Natural Gas Filter Element Model PCHG - 372 In Petroleum Industry

The PCHG372 Natural Gas Filter Element is a premium filtration solution engineered to maintain gas purity in high - pressure pipelines, processing plants, and distribution networks. It actively removes solid particulates, liquid hydrocarbons, and condensate from natural gas streams through a combination of mechanical separation and media filtration. Designed for harsh operating environments, this filter element ensures equipment protection, regulatory compliance, and optimal system efficiency. Its modular design allows seamless integration into new or existing natural gas processing systems.

Model :

PCHG - 372

Element Dimensions:

372 mm × 150 mm × 1000 mm

Product Introduction

Introduction

Suggested Operating Conditions

Applications

3.1 Upstream Oil & Gas

3.2 Midstream Transportation

3.3 Power Generation

3.4 Industrial Use

Technical Data

Features

5.1 Dual - Layer Filtration

5.2 Advanced Media Technology

5.3 Robust Construction

5.4 Low Maintenance Design

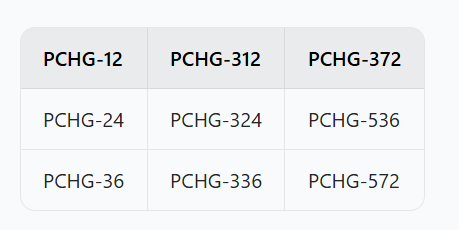

Other models optional

Conclusion

Product Technical Parameters

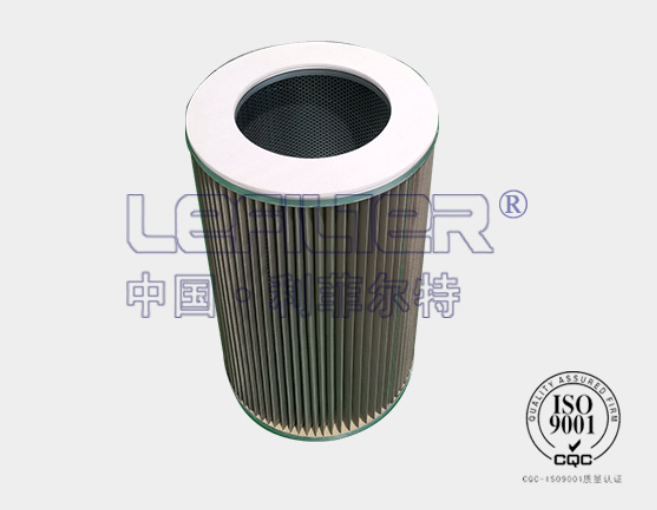

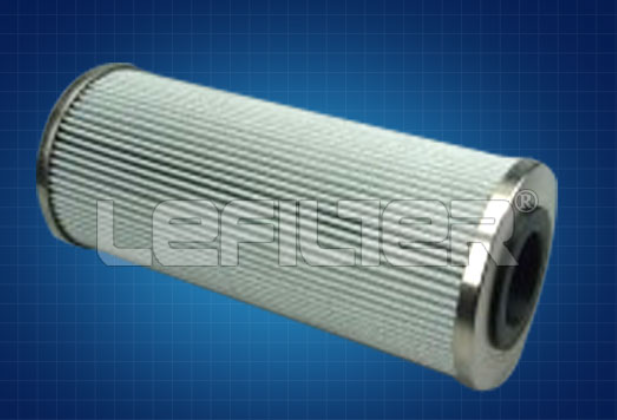

Product Display

ONLINE MESSAGE