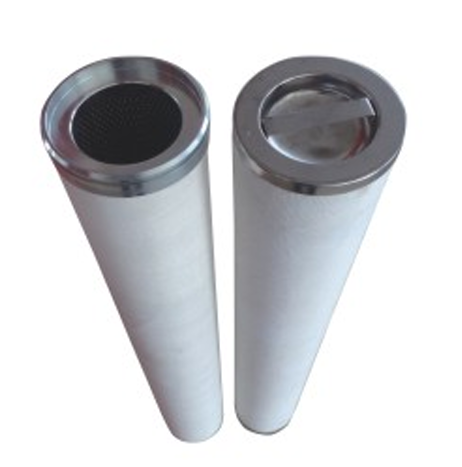

Replacement Pall Coalescer Filter Model CC3LGA7H13 Used In Petrochemical Industry

"LEFILTER’s ISO-certified Replacement Pall Coalescer Filter Model CC3LGA7H13 ensures 99.9% water/solids removal efficiency, direct compatibility with Pall systems, and excels in petrochemical, aviation, and natural gas applications."

Model:

CC3LGA7H13

:

Product Introduction

Introduction

LEFILTER, a leading Chinese manufacturer with over 15 years of expertise in industrial fluid purification, introduces the Replacement Pall Coalescer Filter Model CC3LGA7H13. Engineered as a direct replacement for Pall’s original CC3LGA7H13, this product offers identical performance, durability, and compatibility while delivering significant cost savings. Backed by ISO 9001, ISO 14001, and ISO 45001 certifications, LEFILTER ensures seamless integration into Pall filter systems across industries such as petrochemicals, aviation, and natural gas.

Product Overview

The Replacement Pall Coalescer Filter Model CC3LGA7H13 is designed for efficient separation of water and solids from hydrocarbon-based fluids. Using advanced hydrophilic composite materials, it coalesces emulsified water droplets into larger volumes, which are then removed via gravity separation. This process ensures purified liquids for critical operations, protecting downstream equipment from corrosion and damage.

Applications

Chemical & Petrochemical Industry

Other Industries

Working Principle

The Replacement Pall Coalescer Filter Model CC3LGA7H13 operates through a three-stage process:

Features

Other Replacement Pall Coalescer Filter Models

LEFILTER offers a full range of replacement Pall coalescer filters, including:

Product Technical Parameters

Technical Parameters

Product Display

ONLINE MESSAGE