Hubei Province an oil depot project supporting 150m³ jet fuel coalescer separator site

Project profile

Project profile

Background:

The customer undertakes the construction project of the oil depot. According to the process drawings given by the design institute, the oil depot is a transit oil depot for the storage of aviation kerosene, and each oil transmission link must be equipped with aviation coal filters. The customer contacted us to design the filtration equipment scheme drawings for them.

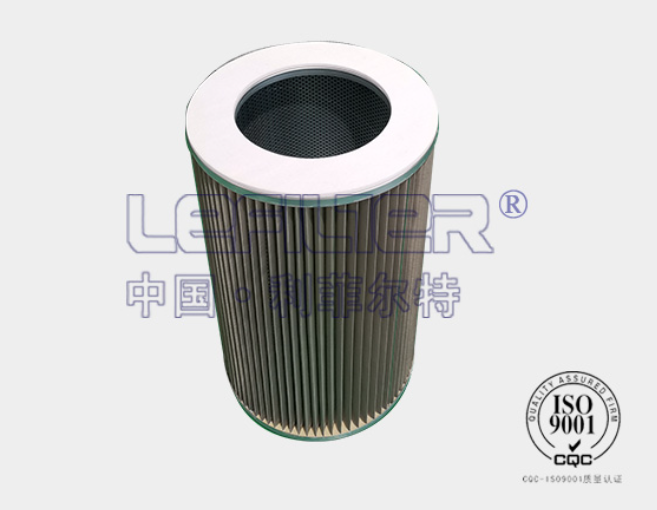

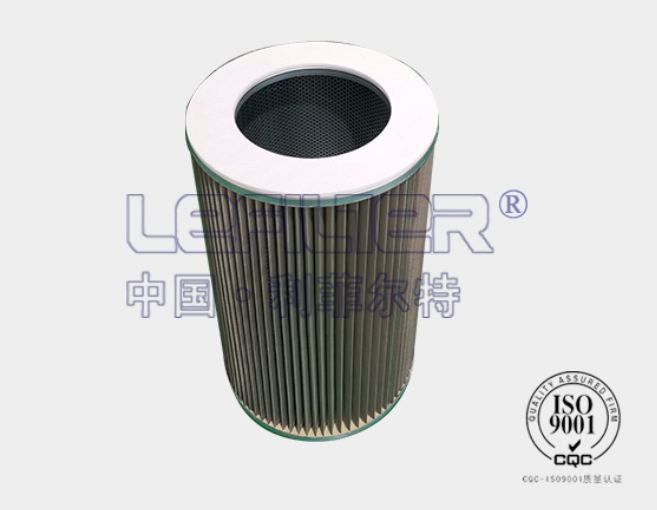

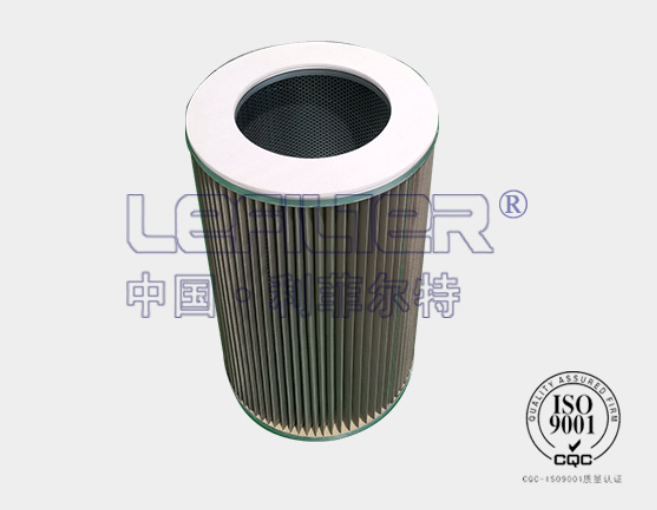

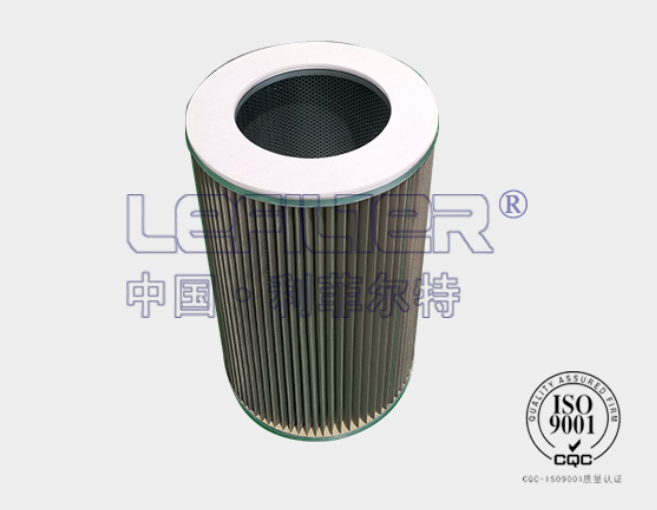

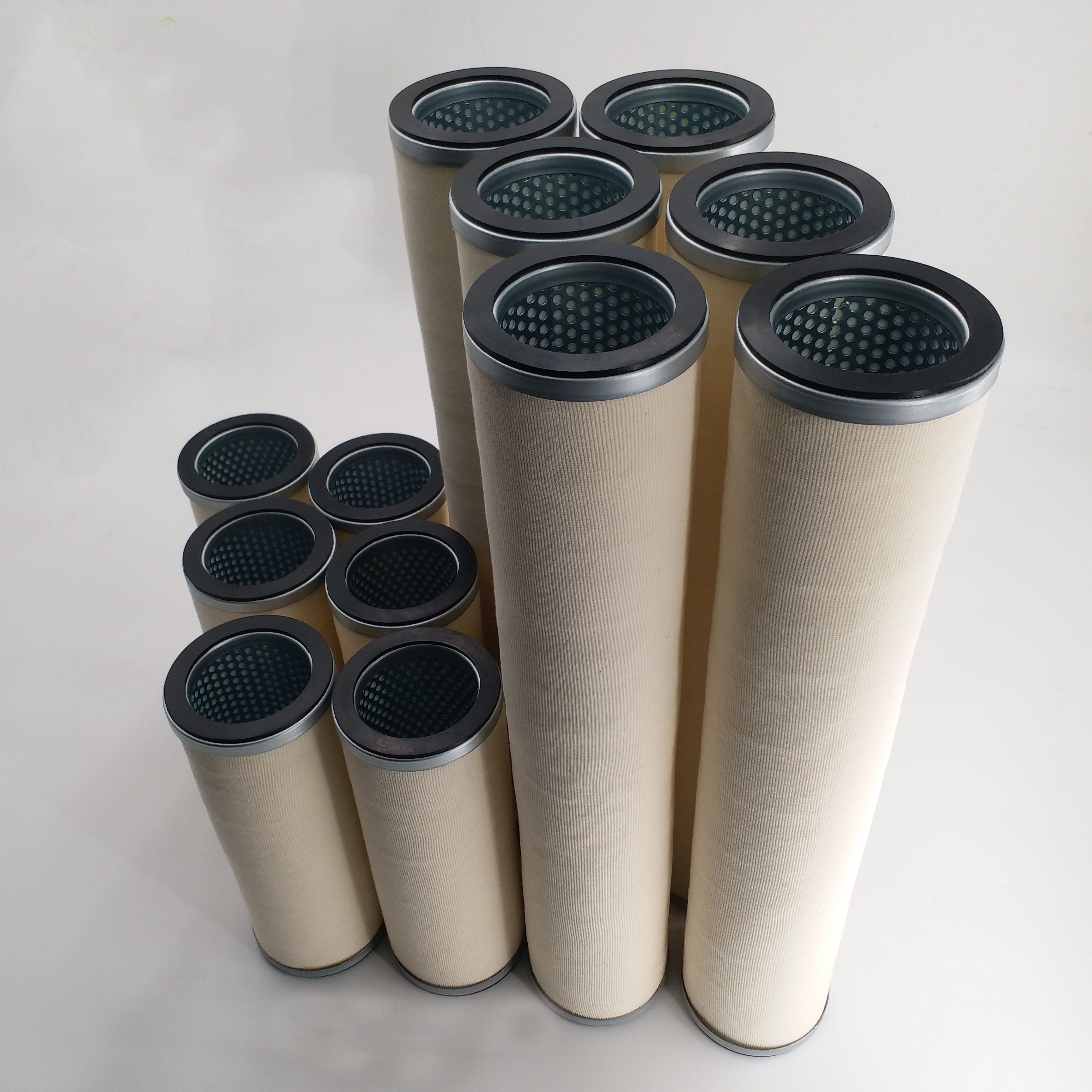

Product introduction:

Aviation fuel coalescer separator as the name suggests, is used to filter aviation kerosene, aviation fuel is mainly used for jet engine aircraft dedicated fuel, due to the special application environment and place, so the performance requirements of aviation fuel is very strict and harsh, usually require ≤15ppm, this time it is necessary to use the filter separator, the water in the oil to the lowest value. It does not affect the quality of aviation fuel.

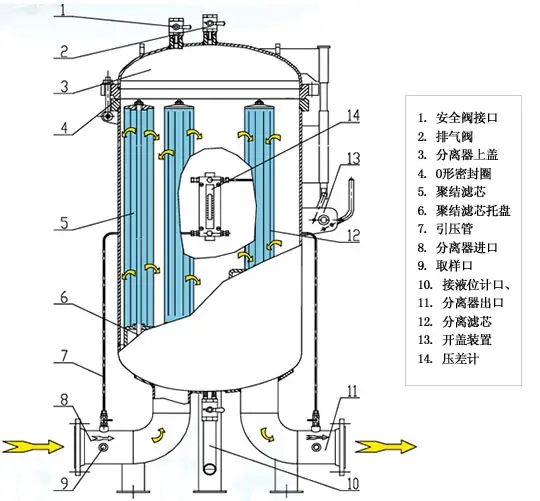

Working principle:

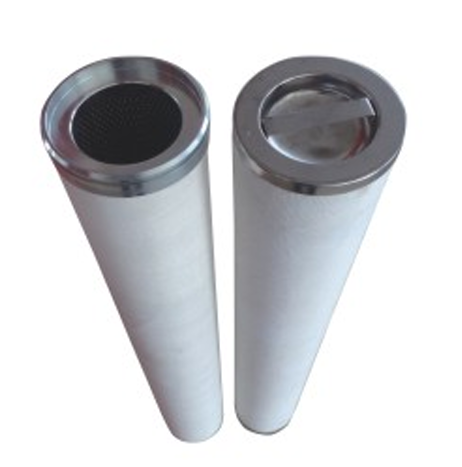

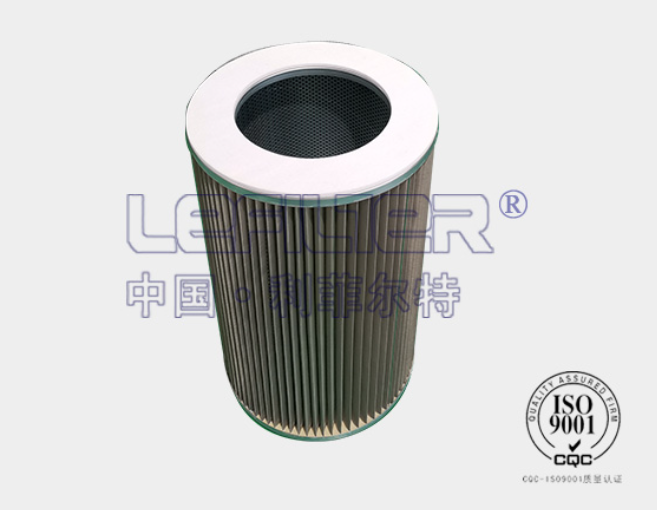

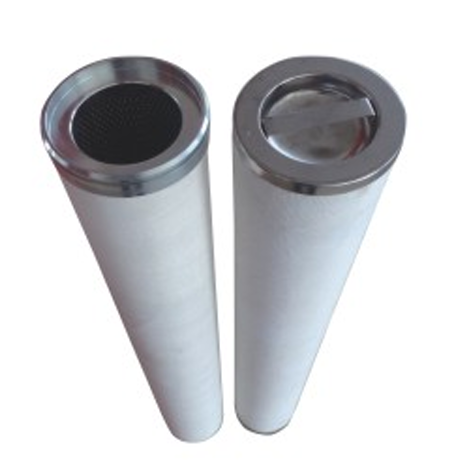

1. The jet coal filter separator consists of a coalescing filter element and a separating filter element, and the double filter element achieves the effect of thorough dehydration.

2. After filtration, the medium that wants to dehydrate flows from the inside of the coalerized filter element to the outside. The first step is to filter out solid impurities by the filter layer; the second step is to separate the oil and water in the emulsified state through the demulsification layer; the third step is to condense the tiny water droplets into large water droplets by the coalerized layer and settle to the bottom of the shell.

3. Part of the future and settling water droplets flow with the medium to the separation filter element, the separation filter element has good hydrophobic performance, and can effectively intercept the water beads to ensure that the filter element after oil and water separation settles to the bottom of the shell.

4. The water settling to the bottom of the housing is discharged regularly by the drainage valve through the oil-water separation interface instrument.

Technical parameter:

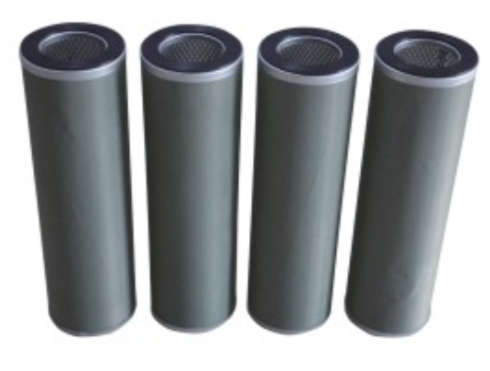

There are a total of 4 positions in the customer site that need to add jet coal filters, 4 150m³ jet coal filter separators on the pipeline in the oil unloading area, 1 100m³ jet coal filter in the oil dumping area, 4 100m³ jet coal filters in the loading area, and 1 100m³ jet coal filter in the emergency loading area. After technical communication with the customer, We have made the equipment selection for the customer, made the design plan, the customer installation and use effect is very good.

Application industry:

It is widely used in the dehydration, purification and separation of various hydrocarbon compounds, vinyl chloride, aviation fuel, gasoline, kerosene, diesel oil, liquefied petroleum gas, naphtha, benzene, toluene, xylene, isopropylbenzene, polypropylbenzene, cycloethane, isopropylbenzene, cycloethanol, hydraulic oil, lubricating oil and so on in the production of petroleum, chemical industry, machinery and electric power industry.

Performance parameter

Performance parameter

Equipment configuration and requirements

Equipment configuration and requirements

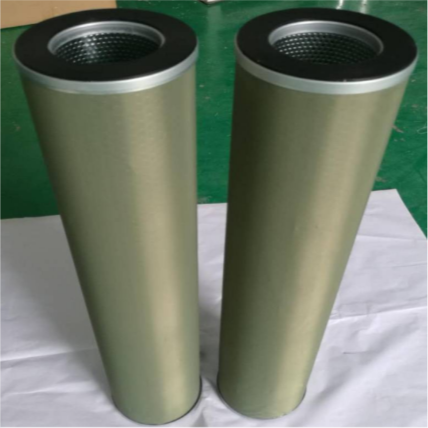

Production and delivery site

Production and delivery site

PRODUCT APPLICATION FIELD

ONLINE MESSAGE