Long transport pipeline workshop aviation filter element replacement case

Project profile

Project profile

Background:

In order to ensure the high standard of aviation fuel quality, the zero-loading position of aviation fuel in the long-distance pipeline workshop ensures the normal shipment of aviation fuel during the peak oil season in summer vacation, improves the quality of on-site management engineering, and implements the full life cycle management of key equipment.

Measures:

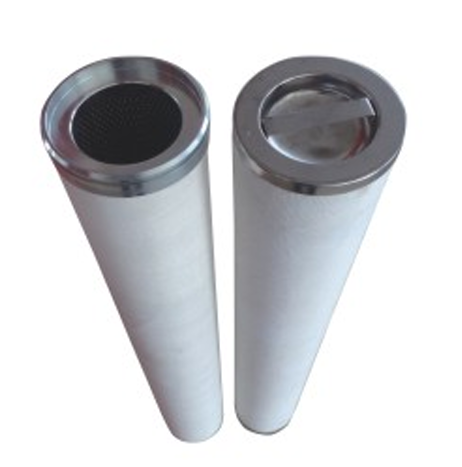

When the workshop uses the account to stop the oil, the filter element belonging to the post will be replaced on August 1. In the early stage of replacement, the technical personnel should prepare the plan in advance, formulate the replacement plan, contact the relevant units to coordinate the production and construction, and open the operation bill. On the morning of August 1, the shift was completed, and the staff completed the preliminary work such as territorial pumping, sealing of the lower well, drawing the warning line, combustible gas detection, and bill verification. Inspection and maintenance personnel clean the filter separator of jet coal, replace the coalesce filter element of the separator, and supervise the relevant departments such as representatives of jet oil during the operation.

Results:

In the face of difficult conditions such as narrow working space and high temperature exposure, all on-site personnel actively cooperated and successfully completed the filter element replacement in one day, laying the foundation for the company to successfully complete the task of aviation fuel highway shipment.

Performance parameter

Performance parameter

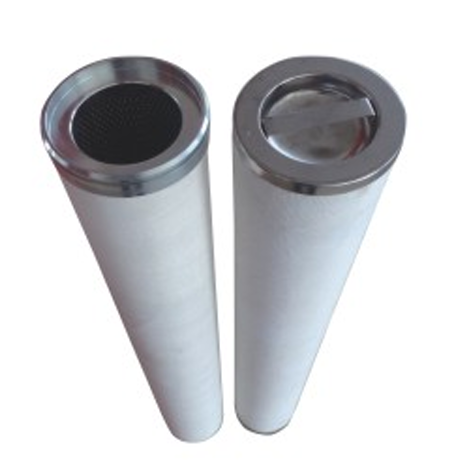

Equipment configuration and requirements

Equipment configuration and requirements

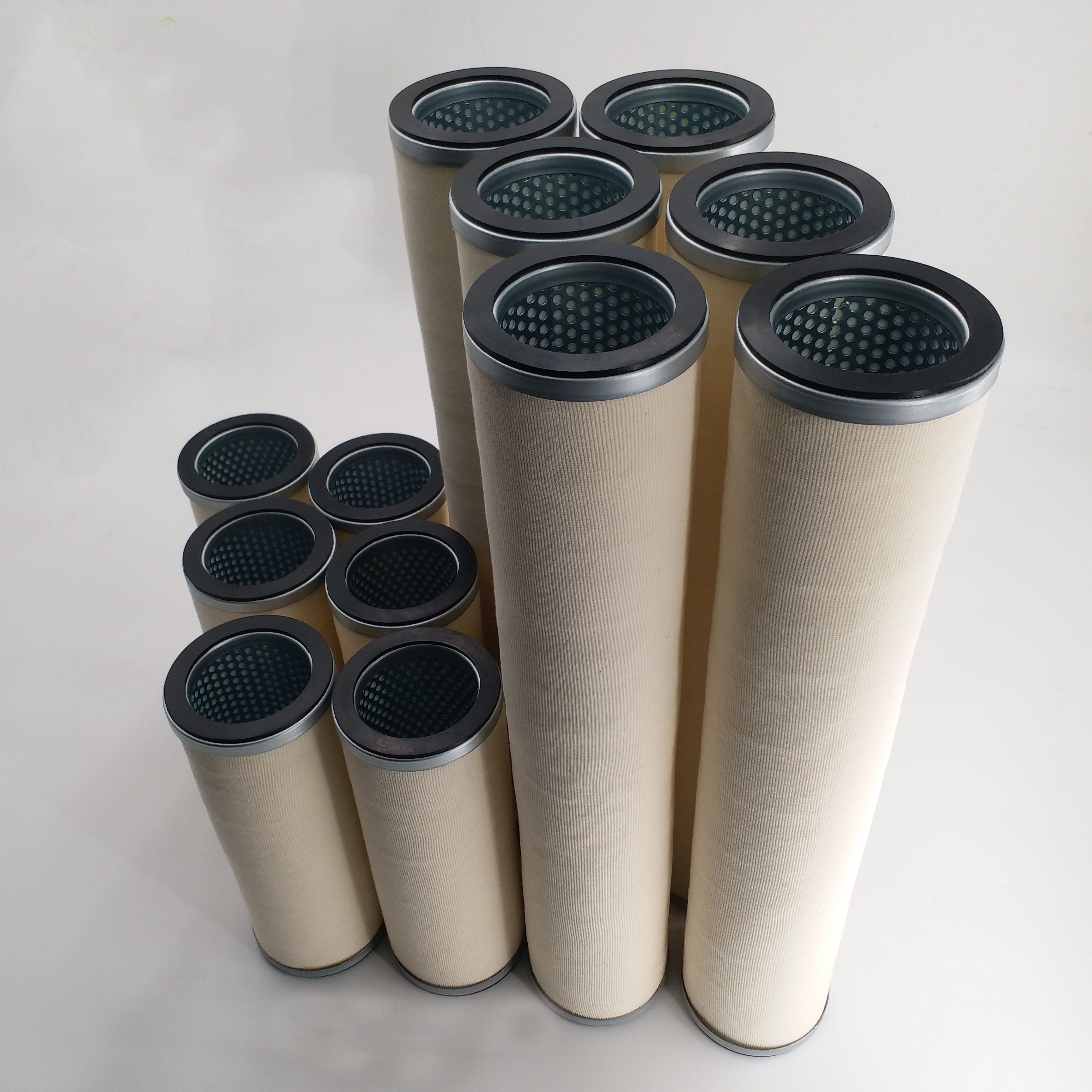

Production and delivery site

Production and delivery site

PRODUCT APPLICATION FIELD

ONLINE MESSAGE